Design of Automated Three-Dimensional Warehouse

Automation of logistics systems

Automated Warehouse

Click here for cross-sorter prices and discounts.

Design of automated three-dimensional warehouse

1. Mechanical system design

(1) High-level shelf design

First, according to the warehouse space and inventory provided by the user, design the overall size of the warehouse and the type of goods stored, and select the form and operation method of the warehouse. Based on this, the number of aisles, layers, columns, and shelves can be determined. And consider the structural form of the shelf, the material and the form of the cargo unit.

(2) Selection of roadway stacker

The specific parameters of DA05170 roadway stacker are:

Form: single column, double fork.

Rated load: 500kg

Walking speed: 4-8m / min

Lifting speed 2 / 12m / min

Walking and lifting positioning accuracy: <± 10mm

Lifting height: ≤22.5m

Effective width of roadway: 1200mm.

After selecting the type of stacker, check and calculate the parameters of the shelf to meet the user's requirements.

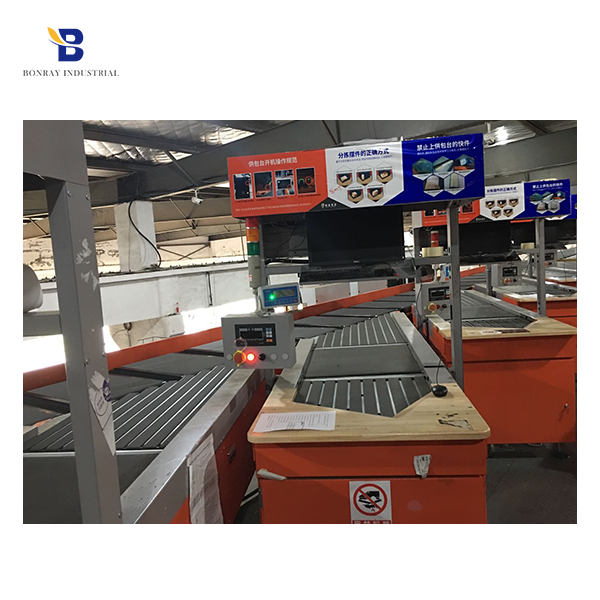

(3) Selection of equipment such as conveyors

Warehouse transportation and transportation must also use a variety of conveyors, forklifts, automatic handling trolleys, elevators and other mechanical equipment to form a transport system for entering and leaving the warehouse. As for the type of conveying device to be used, it should be determined according to the type of goods, the shipping conditions and the structure of the warehouse.

The above content is from Baidu Library "Chapter 9 Logistics System Automation". If the author does not want this article to appear on this website, please contact us to delete it.

Here is a video to know BONRAY cross belt sorter:

Click here to know cross belt sorter products: