VanDerLand Cross Belt Sorter 4

Linear Induction Motor

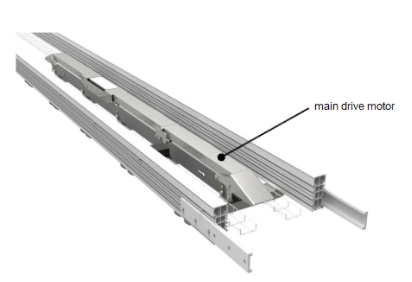

Currently the latest technology in this field is non-contact linear induction motors.

The technology used in linear induction motors is to place a permanent magnet under each running cart. When these magnets pass through the main drive motor between the sorter guide rails, the generated force will constantly push the carrier forward.

The number and position of the main drive motors will be set according to the length of the entire sorting machine, and there will always be one more as a backup motor.

Advantages of this technology:

• Non-contact motor drive, low maintenance

• High energy efficiency utilization (> 50-60%)

• Low noise

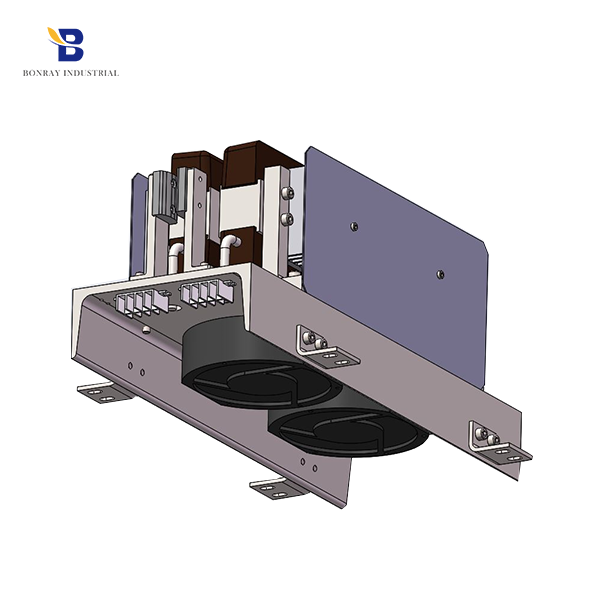

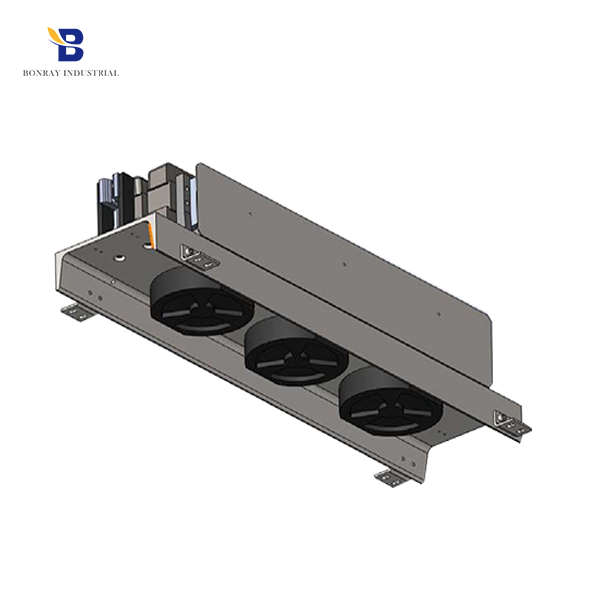

Running Carrier

The running carrier are connected end to end to form a continuous loop on the sorting machine. Each running carrier is relatively independent. Even if a single trolley fails, it will not affect the use of other trolleys. The signal communication of the running car adopts the design principle of plug and play.

Running Car

The sturdy car body runs on the track with 2 wheels. Each wheel is equipped with bearings, because of the low friction of each wheel, even a person can push a 100-meter-long sorter by hand.

Another feature of this wheel is its extremely low noise.

The preset sorting controller monitors the various states of the sorting machine, and transmits the warning information to the central controller of the sorting machine. Tracking the status of each carrier can specify its operation to the maintenance area, and then the operation of replacing the entire operating carrier module can be completed within 10-15 minutes.

The above content is from Baidu Library "VanDerLand Cross Belt Sorter". If the author does not want this article to appear on this website, please contact us to delete it.

This video shows BONRAY CROSS BELT SORTER:

Related Products--Linear Induction Motor