The Composition and Classification of Robots

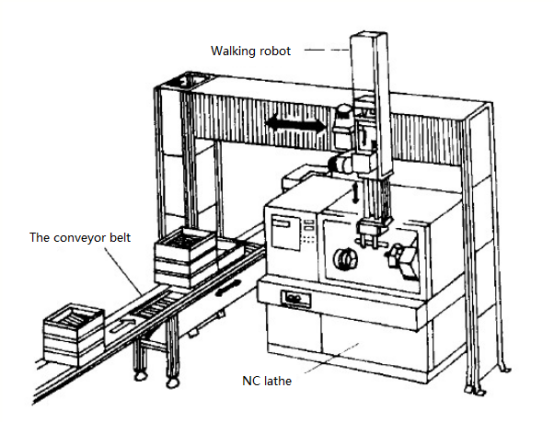

Automation of logistics systems

Handling automation

Handling robot

Definition of industrial robot

Click here for cross-sorter prices and discounts.

It is an automatic controllable, reprogrammable, multi-functional, multi-degree-of-freedom operating machine that can handle materials, workpieces or hold workpieces to complete various operations.

It is a mechatronics automatic device. One of its typical features is controlled by a computer and has (repeated) programming control functions. It is a tool that can replace human beings to perform certain tasks.

The composition and classification of robots

Composition of industrial robot system

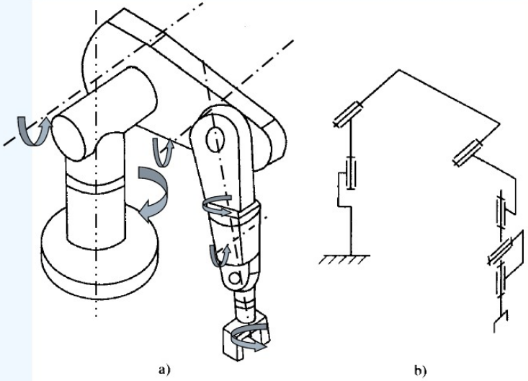

Mechanical structure system

Drive system

Control system

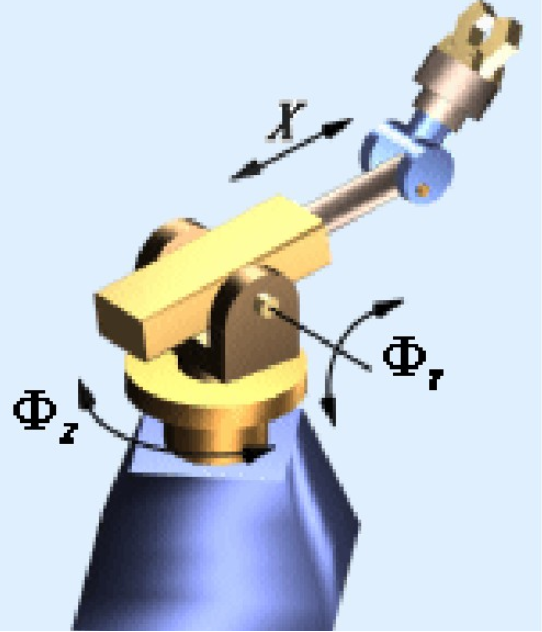

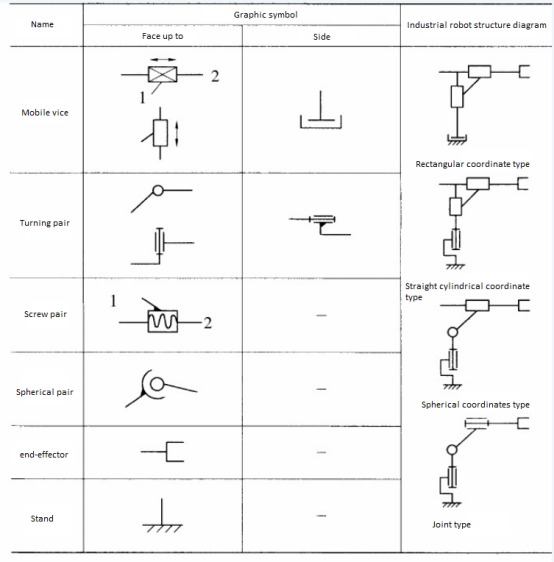

Industrial robot motion function graphic symbol

Mechanical structure system (manipulator)

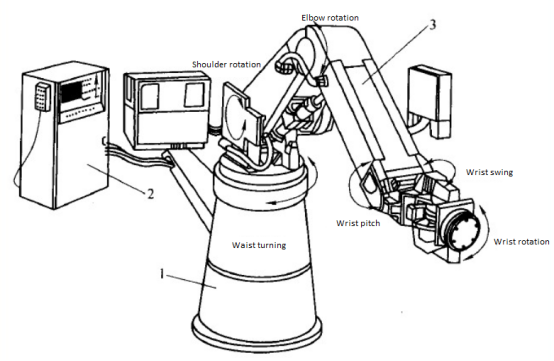

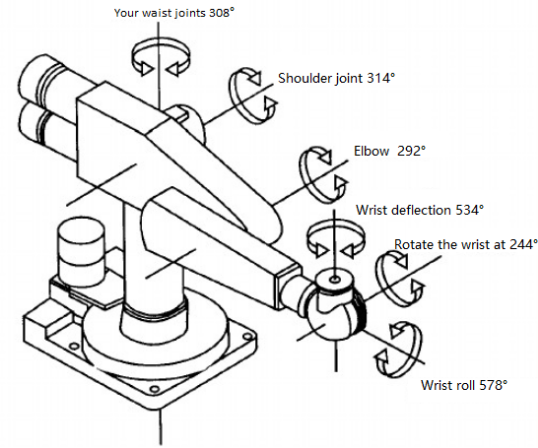

PUMA robot manipulator

Classification by mechanical structure type

Joint Robot

Spherical coordinate robot

Three basic joints: one moving joint and two rotating joints.

Motion graphics: Hollow sphere

Advantages: Because it has pitch freedom, it can complete the task of extracting workpieces from the ground, and the working range is expanded.

Disadvantages: Poor intuitive movement and complicated structure, the position error of the arm end will be enlarged with the extension of the arm.

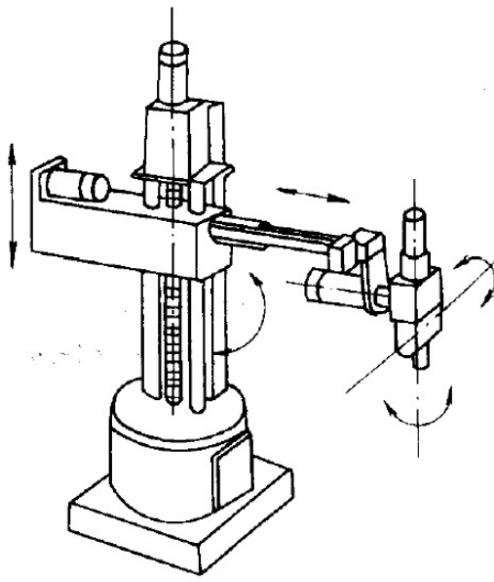

Cylindrical coordinate robot

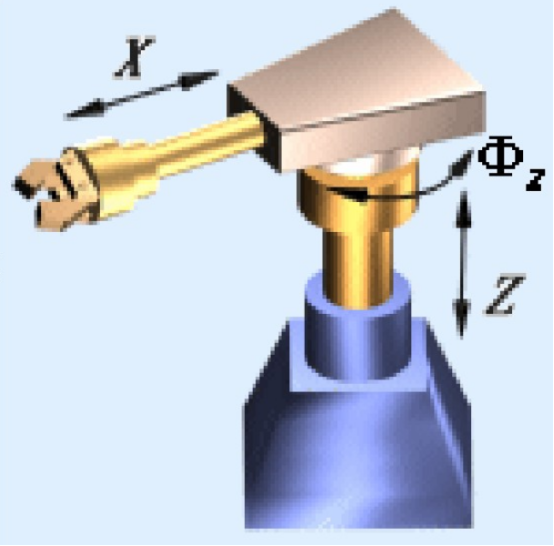

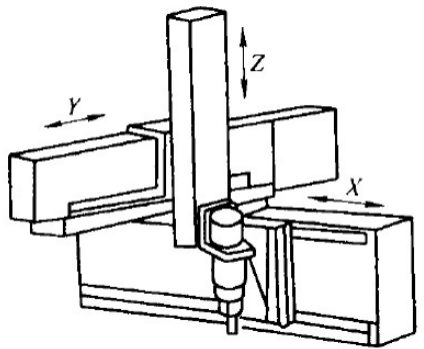

Cartesian Coordinate Robot

Cartesian Coordinate Robot

Cartesian Coordinate Robot

The above content is from Baidu Library "Chapter 9 Logistics System Automation". If the author does not want this article to appear on this website, please contact us to delete it.

Here is a video to know BONRAY:

Click here to know cross belt sorter products: