The Design of Automated Three-Dimensional Warehouse

Automation of logistics systems

Automated Warehouse

Design of automated three-dimensional warehouse

Click here for cross-sorter prices and discounts.

Warehouse overall size design

Three-dimensional warehouse area

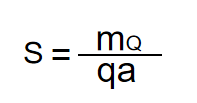

S --- Total area required for three-dimensional warehouse, m2;

a --- Three-dimensional warehouse area utilization rate, which is the ratio of stacking area to total area;

mq --- the storage volume of three-dimensional warehouse cargo, t;

q --- the volume of cargo stacked per unit area of the three-dimensional warehouse, t / m2;

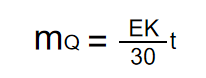

E --- one-month maximum cargo access through the three-dimensional warehouse (calculated 30 days a month)

K --- one by one design maximum storage percentage;

T --- The average inventory period of a cargo in a three-dimensional warehouse is determined based on the statistical analysis of the average inventory cycle of various cargoes over the years;

q = rH

H --- stacking height of cargo, determined according to loading and unloading process requirements, m;

r --- the stock of cargo, t / m2.

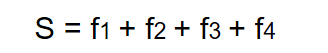

The total area of the three-dimensional warehouse can also be calculated by the following formula

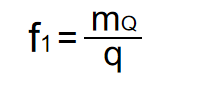

f1--- Effective storage area for storing goods,m2;

f2 --- Warehouse inspection site area,m2;

f3 --- Outbound shipping area,m2;

f4 --- Area of walkway (walkway, carriageway),m2;

The above content is from Baidu Library "Chapter 9 Logistics System Automation". If the author does not want this article to appear on this website, please contact us to delete it.

Here is a video to know BONRAY cross belt sorter:

Click here to know cross belt sorter products: