Two-Line Smart Bus Pick to Light System

Brand: BONRAY

Product origin: China

Delivery time: 30 days

Supply capacity: 1000 sets/day

1.Easy and convenient operation and installation for two-line bus pick to light system.

2.The two-line bus pick to light system is designed with two-way communication technology.

3.The OLED dot matrix, English and Chinese language display options for the electronic tag of two-line bus pick to light system.

4.The two-line bus pick to light system realizes optimal management for warehousing operation.

-Introduction of pick to light system :

The logistics and warehousing industry has entered a period of rapid development currently. A great number of advanced technologies and equipment are commonly used in logistics or warehouses fields. The pick to light system is one of these innovated technologies. The pick to light system includes a set of electronic label equipment installed on the storage's shelf. Through the control of computer and software of PTL system, the light signal and digital display of digital assorting system are used as auxiliary tools to guide the pickers to complete the picking work correctly, quickly and easily. The pick to light system can flexibly control the picking process and monitor the picking status on site simultaneously.

The digital assorting system can reduce the picking error rate, increase the picking speed and avoid the high labor expense. The digital assorting system realizes the paperless picking mode as a series of electronic tags mounted on the shelf that replace the picking list. These tags can indicate the types and quantities of the goods so that the pickers do not need to rely on memory to work. According to prompt of the pick to light system's light, the goods can be selected accurately. The working principle of digital assorting system is that the antenna pass the signal between the electronic tag on the shelf and the reader. The computer transmits the order's information to the electronic tags so that the pickers can complete the work according to the guidance.

-Two-Line Smart Bus Pick to Light System:

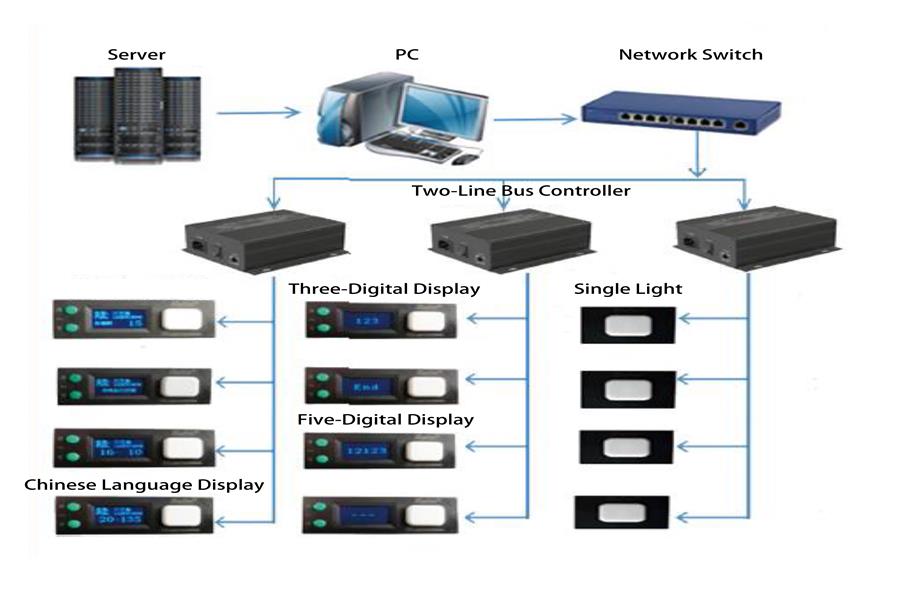

As the two-line smart bus digital assorting system, it adopts the two-wire intelligent bus method for the picking label which are the power line and communication line. The data sources are from the WMS, ERP or MES system, etc. The out-of-store information can be manually typed in. The pick to light system's PC is used to download the Ex-warehouse order from WMS and send the information to two-wire smart bus module via the network switch. It also process the data which are returned through the two-line pick to light system simultaneously. The network switch can extend from one interface to multiple ones, it is also known as a bridge. The controller can be used to operate the signal light and the subtitle machine electronic label for transmitting the task back to PC by two-way communication line.

The two-line smart bus pick to light system is composed of three kinds of electronic labels. There are 3-digit label, 5-digit label and single light label. The 3-digit label is designed to display Ex-warehouse quantities and issue instructions. The 5-digit label is used for showing the cargo position, Ex-warehouse quantities and issue instructions. Connecting alarm lights and indicate instructions for picking tasks are the purposes of single light label for digital assorting system.

-Advantages of two-line smart bus pick to light system:

1.The electronic label of two-line smart bus pick to light system is designed with embedded rail wires that is easy and convenient for operation and installation.

2.Low power consumption which is less than 0.2W for the electronic label of two-line smart bus digital assorting system.

3.The two-line smart bus pick to light system can drive various numbers of devices for commanding, monitoring and controlling them simultaneously and smoothly by two-way communication.

4.The OLED dot matrix display for electronic tag can be set up in either Chinese or English language.

5.The adopted PVC flame retardant material of the pick to light system's electronic tag follows the standard safety regulations.

6.The two-line smart bus digital assorting system is installed with reliable wireless communication system for data transmission. One area controller can operate up to more than 900 electronic tags at the same time.

7.The job performance of pickers can be analyzed through the pick to light system.

8.The digital assorting system realizes easier and optimal management for the operation route and storage arrangement.

-Parameters of two-line intelligent bus controller for pick to light system :

JYZK-B1 Single Output Intelligent Bus Controller | JYZK-B2 Dual Output Intelligent Bus Controller | |

Rated input voltage | 220V | 220V |

Operating voltage range | 100V-264V | 100V-264V |

Communication distance | 500 meters | 500 meters |

Maximum input current | 1A | 1.5A |

Ethernet interface | 10M/100M self-applicable | 10M/100M self-applicable |

Operating ambient temperature | -35°C~70°C | -35°C~70°C

|

Number of bus output channels | 1 channel

| 2 channels |

Number of bus downlink labels | <128

| <128

|

Normal working temperature rise | <20K | <20K |

Network port working mode | TCP Client TCP Server UDP Client UDP Server | TCP Client TCP Server UDP Client UDP Server |

Installation size | L-155mm W-147mm H-55mm

| L-170mm W-145mm H-60mm |

-Parameters of electronic labels for two-line bus pick to light system:

-Use of two-line bus pick to light system:

The two-line bus pick to light system is widely used nowadays by it's various of functions such as comprehensive management system, constant data collection and private data channel. It is mostly used in pharmaceutical industry, clothing industry, refrigerated warehouse, chemical industry, etc.