Steerable Wheel Sorter

Brand: BONRAY

Product origin: China

Delivery time: 30 days

Supply capacity: 500 Sets

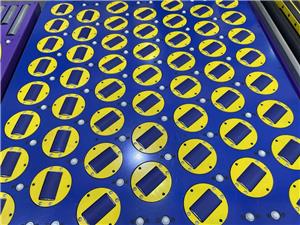

1.The material of coated divert sorter roller adopts the high quality imported rubber, nylon, polyurethane or aluminum alloy so that the roller can possess optimal abrasion and tear resistance.

2.According to the steerable wheel sorter's 'front-end' programming management system, it reaches the combined functions of shunt, confluence, and rotation that greatly reduces the labor cost.

3.Constant drive between the wave sorter roller and product that allows the product to be steered rather than tossed.

4.Customized service for different dimensions and specifications of switch sorters.

5.The steerable wheel sorter's outstanding signal collective system has accurate sorting performance.

Steerable wheel sorter, also known as inclined balance wheel sorter, swivel wheel sorter or divert sorter that is specially designed for e-commerce express logistics for sorting packages, boxes, bags, bottles, books, parcels or electronic products. The wave sorter is mainly composed of conveying roller, synchronous steering controller, transmission device and frame.

The steerable wheel sorter is driven by a motor to lift the oblique guide wheel or change the original linear motion direction of the oblique guide wheel so that the oblique guide wheel drives the goods to move toward the sorting destination chute or the distribution conveyor automatically. This design of switch sorter allows the sorter to be easily re-located along the conveyor path if divert locations change. When a load requires diverting, the control logic simultaneously rotates and increases the speed of all the divert sorter wheels to effectively accomplish the divert action. The conveyed load is diverted from the conveyor at 30, 45, 60 or 90 degrees. Once the load has diverted, the wave sorter wheels rotate back to the forward direction. The swivel wheel sorter module is bolted into the side frame of the conveyor while the controls are configured and connected.

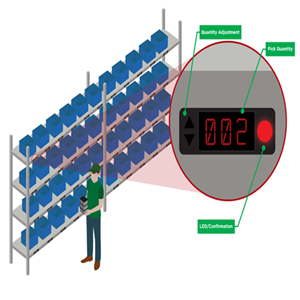

The function of synchronous steering controller for the wave sorter is to identify, receive and process the signal. It can instruct the sorting device by the signal so that to perform automatic sorting process according to product types, delivery locations or categories of owners. These different kinds of sorting requirements can be entered into the system of swivel wheel sorter in various of ways such as barcode scanning, keyboard input and weight detection, etc. The switch sorter can determine which product should enter the sorting destination chute by signal.

The maximum sorting efficiency of the steerable wheel sorter is up to 8000 pieces/hour. The swivel wheel sorter has compact structure, easy installation and disassembled instruction with noise less than 65 dB. Another highlight of this wave sorter is that it has outstanding modular design that each part can be easily accessed and replaced so that to minimize the downtime. The switch sorter is suitable for flexible conveyor, roller conveyor, belt conveyor, etc.

-Parameters of divert sorter:

Sorting Capacity | 5000-8000 pieces/hour |

Sorting Angle | 30°/45°/60°/90° |

Maximum Loading Size | 1200mm*900mm*800mm or Customized |

Loading Weight | 50g-50kg |

Sorting Speed | 1.0m/s-2.5m/s |

-Use of the steerable wheel sorter:

The wheels of divert sorter turn to forward direction for conveying products straightly on conveyor in transport mode. This swivel wheel sorter can work consecutively more than 100 hours. It is widely used in e-commerce, express delivery, fresh cold chain and other logistic industries for transmission of medicine, books, tobacco, shoes, clothing, maternal and infant appliances. The wave sorter also has excellent performance for fragile goods such as liquor and beverage's transmission.